Tool making is an integral part of blacksmithing. There are so many tools to make in the blacksmith shop: tongs, hammers, punches, chisels, drifts, hardy tools, jigs, fullers, swages, etc. On the farm, there are rakes, pitchforks, shovels, scythes and sickles. In the kitchen, there are knives, spoons, bottle openers and on and on. There is an endless fleet of steel tools to be forged!

When I began working with metal, I didn’t think I’d be making belt buckles. But isn’t a belt buckle just another tool?

Other than holding up one’s pants, I’ve found that making belt buckles is a great way to experiment with the various textures, colors and forms available when working with metal.

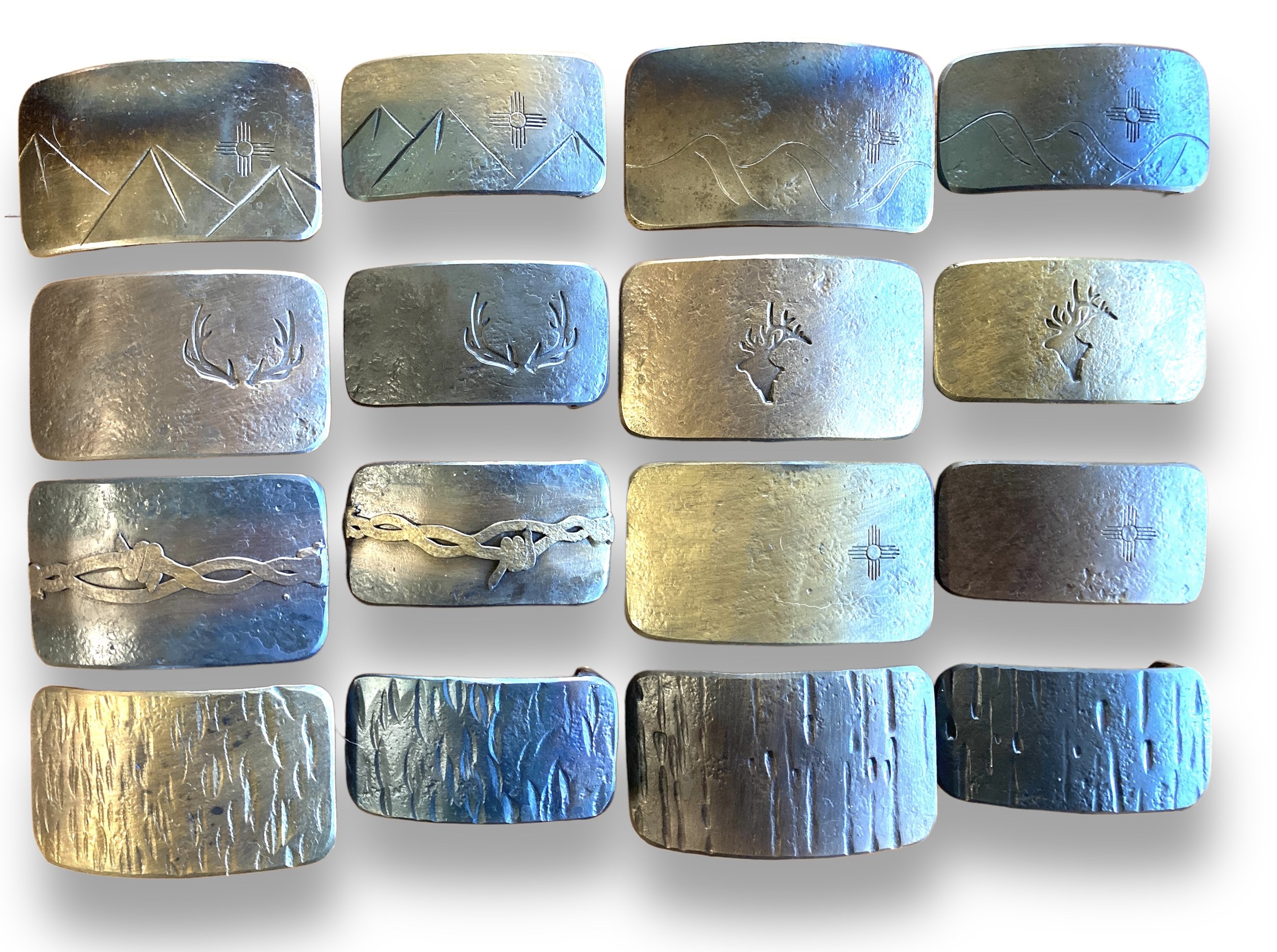

There are myriad textures to be achieved in metals via blacksmthing. From punching out shapes with square or circular punches, varying one’s hammer strikes or types of hammers, or even applying weld marks will yield interesting results.

‘Waves’ hand-forged belt buckle. Texture achieved through use of a hand-sledge with a sharp round edge swung repeatedly at an angle.

Square punch marks tested on a a small hand-forged dish. I made a standard, handled square punch which was used to assess a pattern of square marks. Looking forward to applying this technique to belt buckles (and light-switch plates) later this winter.

‘Welded Panels’ hand forged belt buckle. This is one of my favorites. Here, strips of steel are fused via sloppy weld beads. I then forge them flat to get this unique texture.

In my limited pursuits, I’ve managed a lot of color variation. Applying a heat gradient through polished steel (and other metals) yields oxidation color gradients - which in steel can be very striking and interesting. Depending on temperature, these gradients can be captured in the final piece in unlimited ways. In addition, various tones can be wrought through brass plating at different temperatures. Mixing these techniques results in a lot of different coloring combinations.

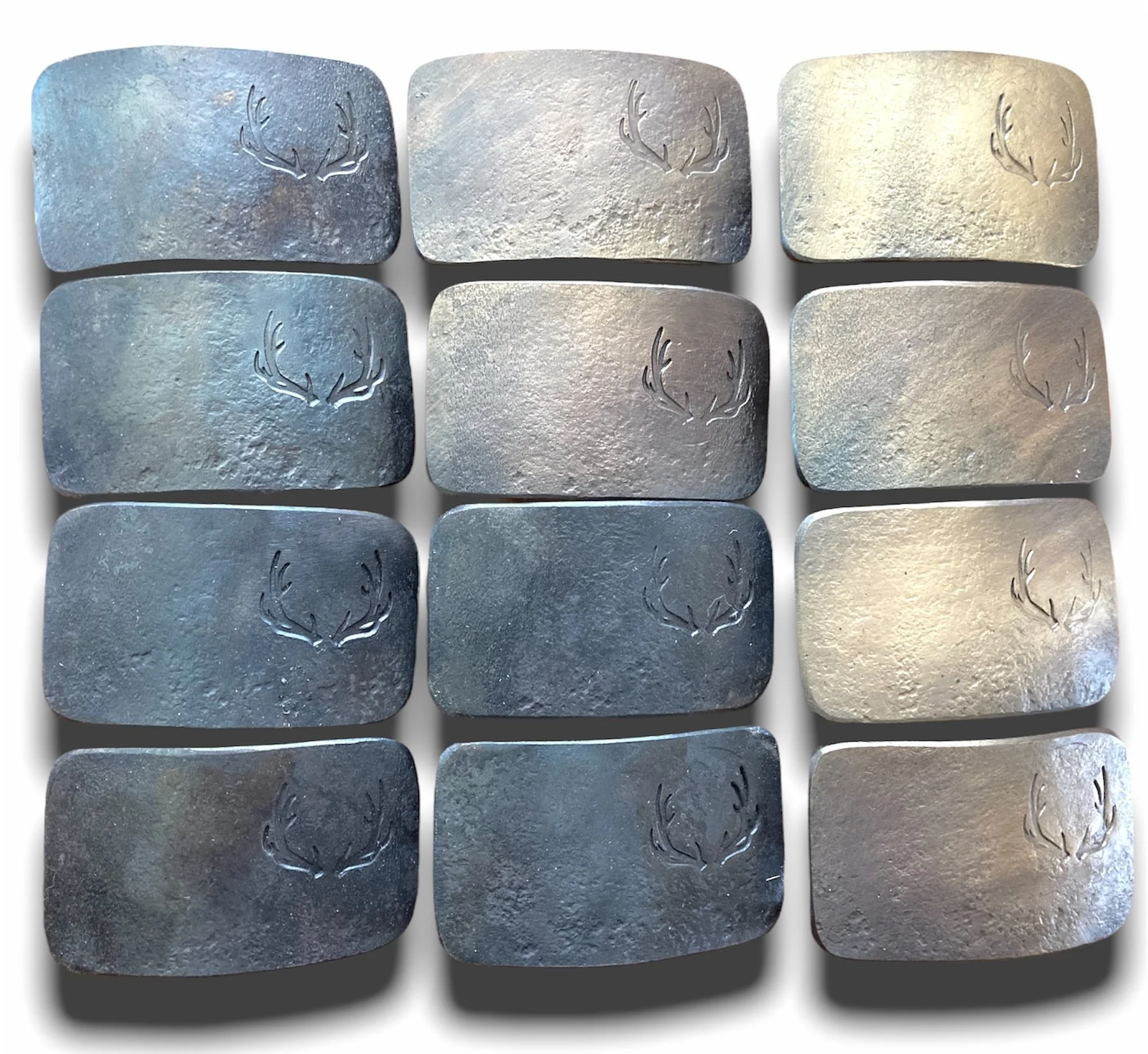

“Elkhorn” hand-forged belt buckle. The color gradient shown here is achieved by uniform heating of the buckle to a specific temperature before ‘arresting’ it with a quench.

‘Barbed Wire’ belt buckle. Super fun to make. The coloring here is made by ‘running the colors’ across the buckle via asymmetric heating.

All lined up for a size comparison. A variety of Meridian hand-forged buckles shows an assortment of color possibilities.

Lastly, blacksmithing permits endless experimentation with forms. As far as a plate-style belt buckle perhaps things are more limited. However, our Barbed Wire belt buckle is still a good example. I appreciate the contrast between the flowing aspects of the barbed wire and the more rigid plate background. Similarly, the barbed wire cutouts can be manipulated such that each buckle is uniquely different from the next. Some other examples below as well.

Our ‘Topo Buckles’. I made a set of custom, tiny walking chisels for myself out of some old drill bits. These have been the perfect tool for fine cold chiseling. Topographic renderings are adapted from USGS contour maps to represent favorite summits on a belt buckle. Mountains are medicine….

Our ‘Barbed Wire’ Belt Buckles; each one is unique. Spent wire from the farm finds new life on a belt buckle. And the animals appreciate less barbed wire around. I love the contrast here between the highlighted wire and the dark background.

Our ‘Crescent Horseshoe Buckle’. Spent horseshoes are reborn as belt buckles. The horseshoe aspect is maintained, but also takes on a whole new form with the tapered, crescent shape. Watch a short clip of these being made!

Blacksmithing opens up worlds of possibilities for experimentation. So much so that it is at times overwhelming! Making hand-forged belt buckles has been a wonderful way to pick a discrete, forged offering and apply a variety of methods in order to both hone specific techniques as well as offer a range of unique items.

Click below to check out our variety of belt buckle offerings, or contact us to learn about custom forged works!